inch step will give double the rotation as

long as the pitch is constant.

Measuring the cup is done the same

way with the smallest step. However the

cup pitch may not be the same as

measured by the Orlic gauge. This is

because we are looking at a small area of

rapidly changing pitch differently. Both

gauges measure the average pitch over

different areas. If we use the smallest

rotation for the Orlic gauge and the

smallest step for the Wood/Speedmaster

gauge, the cup reading would only be the

same if the Wood/Speedmaster gauge

reads five degrees and the Orlic gauge

reads .0625 over the cupped area. It

doesn’t really matter, except when

comparing readings that may be taken

using different gauges.

Another propeller parameter is the

blade rake as shown in the blade cross

section picture above. This can be

difficult to measure, especially if the

propeller doesn’t have a straight rake

that goes through the propeller axis.

Place a small straight edge along the

blade to find a position where it touches

from hub to tip. The angle this makes

with the axis is the rake. Most stock

model propellers have the same rake

from leading edge to trailing edge and

the rake line goes through the shaft axis.

That situation is what the blade cross

section picture above shows. A way to

generate this kind of rake will be

discussed later.

The final propeller parameter we will

discuss is the blade area. Part 1 showed

the various ways this could be measured.

It showed a cut using circular arcs to

shape the projected blade outline. The

area of these arcs was easy to calculate

(Continued on Page 6)

PROPWASH

April 2014

5

area, you should get the same .05

reading in most areas of the blade from

hub to the outside edge. As cast, I get

between .049 and .052 most places on

the blade with my pitch gage. If you pick

a ten degree rotation, the indicator

reading will be twice as big or .10 inch

in a constant pitch area. Props with

progressive pitch will usually have

higher readings (increasing pitch) as you

go from the leading edge to the trailing

edge. Many propeller modifiers add

progressive pitch to stock props.

Cup is measured in the same way.

Usually you will need the smallest

rotation stop to stay within the cupped

section. Even so, you are actually

measuring some average pitch in an area

of rapidly increasing pitch. Our example

has a fairly constant indicator reading

of .085 (2.16 mm) where the five degree

rotation is in the cupped area. That

makes the average pitch in the cupped

section .085 x 72 = 6.12 (155.4 mm).

The Wood/Speedmaster style gauge

is a little harder to understand, even

though it measures the same thing as the

Orlic gage. With the same ABC 2018

prop as above I will go through the

calculations. These gauges come with a

pitch chart, so you don’t need to do any

math. Here we use a fixed step set by the

black stepped wheel and measure the

rotation. This time we calculate the

fraction of a full 360 degree rotation the

step represents. For the lowest .0625

inch (1.59 mm) step the gauge should

read 6.25 degrees on our 3.6 inch pitch

prop. That is 1/57.6 (360 divided by 6.25

is 57.6) of a full circle so the pitch would

be 57.6 times .0625 (the step height) or

3.6 inches as above. Again, this rotation

should be constant over all but the

cupped area in the stock prop. A .125

There are many ways to measure

pitch. Today modelers usually use one

of two pitch gauges. The Orlic style

gauge measures the distance the blade

advances with a set rotation. There are

variations on this gauge, but the

principles are the same. The Wood/

Speedmaster style gauge measures how

many degrees a blade needs to rotate for

a fixed advance. The older Hughey

gauge uses the same principle but with

less precision.

As you can see in the picture above,

the Orlic gauge has a dial indicator and

a series of stops that define the amount

of rotation for the measurement. To find

the average pitch in the area you are

measuring, divide the indicator reading

by the fraction of the circle. Let’s use an

ABC 2018 prop as an example. The

nominal pitch is 1.8 times 2.0 inches or

3.6 inches (91.44 mm). If you pick a

five degree stop and measure some-

where in the middle of the blade, the

dial indicator should read .050 inches

(1.27 mm). Five degrees is 1/72 of a full

circle so the pitch will be .05 times 72 or

3.6. Because this prop has a constant

pitch everywhere except in the cupped

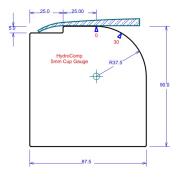

Cup Gauge

Orlic Pitch Gauge

Wood/Speedmaster Pitch Gauge

A 3-D view of a full propeller