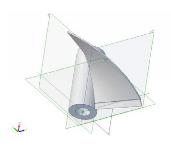

The shape in this case is thicker at the

hub and is raked (explained later) 20

degrees.

We revolve and advance this cross

section forward at the basic pitch to

create most of the blade surface and

rearward at a higher pitch to create the

cupped section. The pitches can be

constant or varying as the shape revolves

along the axis. A varying pitch is often

called progressive pitch and may be

described as progression percent.

Cup can be measured several ways.

In the above example we used an

increased pitch for a small distance. That

is very similar to a method suggested by

HydroComp. Cup is used to increase the

effective pitch of the prop. They found

in full sized props that this increase was

around 21 times the height of the cupped

section. That is, a 250 mm diameter prop

with a 1.85 mm cup had an increase in

effective pitch of around 39 mm. They

suggest using a cup gauge with various

steps like the ones pictured on page 5.

We effectively measure cup in a similar

way with our pitch gauges as explained

in the following.

PROPWASH

4

April 2014

In Memory of Wreno Wynne

By Wes Wynne

North Texas Battle Group

My father was a rare individual who

could brighten anyone’s day. He will

be dearly missed by many.

Model warship combat attracts

different people for different reasons.

Some enjoy the strategy of combat,

others appreciate the history, some like

the technical challenges, and some just

get a kick out of shooting things to bits.

For my dad, the hobby was about the

close friendships he developed all over

the world. He loved helping others

with the various technical and

engineering problems they

encountered. More to the point, he

spent more time helping others with

their challenges than working on his own ships. His enjoyment came from the close

camaraderie with others. As many have said, Combat will never be the same without

him.

Editors Note: Wreno Wynne was the NAMBA Combat Chairman from 2008 until

his recent passing. He was most known for being a member of the North Texas Battle

Group in District Seven and coordinating the annual North American Big Gun Open

Championships in Kaufman, Texas.

Props Part 2 – Geometry

By Lohring Miller

NAMBA Safety Chairman

Now that we’ve covered some of the basic propeller theory, let’s look at an actual

prop. There are two ways to visualize how a propeller works. Starting with the Wright

brothers, aerodynamic engineers have thought of a propeller as a rotating wing. We

looked at the blade sections in the October 2013

Propwash

Part 1 this way. Long

before this, marine engineers thought of a propeller as a screw advancing through

water in the same way as a screw advances through a solid object. We are going to use

this system to explore propeller geometry.

By far the most important dimension of a propeller is its diameter. Remember from

Part 1, that the power absorbed varies as the fifth power of the diameter. Very small

changes in diameter result in big changes in the power needed to turn a given rpm.

Fortunately, diameter is easy to understand and measure. A three blade propeller, or

individual blades of any propeller, can be measured by measuring from the blade tip

over a shaft through the center. Subtract one half the shaft diameter and you have the

blade radius.

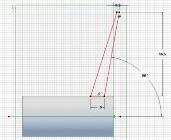

The next feature of a propeller we need to

measure is the pitch. A propeller’s pitch is

the same as a screw’s. It is the distance a

screw advances through a solid in one

revolution. Our propellers are usually made

with constant pitch from the edge to the hub.

However, because the circumference is

smaller at the hub than at the tip, the blade

angle at the hub will be greater. You can

visualize this as a shape revolved and

advanced around an axis like that in the

pictures in the next column.

Propeller Blade Radius Measurement

A propeller blade cross section

Cross Section Rotated and Advanced

Along an Axis