This effect is different from cavitation where the pressure

on the blade drops below the boiling point of water forming

a water vapor bubble. Supercavitating propellers are fully

submerged. Below are the efficiencies of a family of

France Helices surface piercing props.

Note that the efficiency increases with pitch to diameter

ratio, at least to pitch to diameter ratios a little above 2.

Note also that the efficiency is a little lower than

conventional props at the same pitch to diameter ratio.

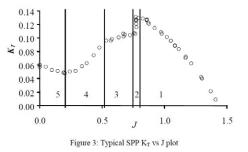

Below is a typical thrust to speed (advance ratio) graph of a

surface piercing prop.

Compare it to the smoother curves for the conventional

props. Area 1 is very similar, but the other areas show

increasing thrust with speed then a sudden jump. This is

what is observed when a boat is launched and the prop

“cavitates”. Then the prop hooks up and the boat accelerates

normally. What is happening is that the blade is fully

ventilated at the beginning (areas 3, 4, and 5). As the speed

increases, the blade becomes partially ventilated and starts

to act more like a normal submerged prop.

However, the surface piercing prop has less than one

half of its diameter in the water. The best efficiencies occur

in region 1 of the graph a little after the transition region 2.

What does this mean for blade design? The loading and

unloading of the blade as it enters and leaves the water

requires high strength. The main part of the blade

contributing thrust is the rear (back) surface. The front

surface operates at close to atmospheric pressure, a much

lower value. Below are several blade hydrofoil shapes used

for surface piercing props. Remember, the prop acts like a

submerged prop at low speeds and is only partially

ventilated at high speeds. The first design is a standard

Continued on page 26

PROPWASH

October 2013

25

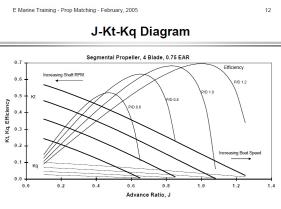

Engineers graph propeller thrust and torque against speed with

graphs like the one below for a family of conventional propellers.

Notice that there is a narrow band of peak efficiency for a given

pitch to diameter ratio. This reflects the fact that when the speed gets

too high, the blade element of the propeller is starting to run at a low

or negative angle of attack to the water flow. When the speed is too

low, the blade element starts to generate more drag from too high of

an angle of attack. The pitch, therefore the blade element angle of

attack, needs to be matched to boat speed and rpm. Note also that

efficiency increases with higher pitch propellers running fast.

So how are surface piercing propellers different from those

illustrated above? As the propeller enters the water it draws air from

the surface with it. This forms an air pocket on the forward face and

trailing edge of the blade under fully ventilated conditions. The

water pressure on the back of the blade generates most of the thrust.

Only part of the propeller’s diameter is in the water, eliminating the

drag from struts and shafting. This is a big advantage in fast boats

where appendage drag is very significant.