Of course, real propellers don’t “screw” through the

water. The difference can be thought of in two ways. The

easiest is the ratio of the actual advance to the theoretical

advance in one revolution from the pitch. This ratio of pitch

times rpm to speed is called slip. If the slip is zero, the

blade element is operating at zero lift and there is no thrust.

Engineers use a different measure that compares diameter

times rpm to speed called the advance ratio, usually

represented as J. Propellers are usually compared on the

pitch to diameter ratio. The engineering graphs will all use

the advance ratio, J. For the mathematically inclined, the

common engineering relationships are shown in the picture

on page 25.

PROPWASH

24

October 2013

Props – The Theory Part One

By Lohring Miller

NAMBA Safety Chairman

Propellers are the black art of model boat racing. In this two part

series of articles I hope to improve your understanding of how props

work and how to modify a cast blank into a racing prop. The first

part will go over some basic propeller theory. The second part will

describe the details of propeller finishing, modification, and

measurement. I’m depending heavily on

Propeller Selection for

Boats and Small Ships,

a course by Chris Barry, for the theory

section of this article.

You can think of a propeller as a magic device that takes water

and throws it backward. This creates a force proportional to the mass

of water and its speed according to Newton’s law of motion. The

ratio of this thrust to the weight of water passing through the

propeller is the thrust load coefficient. The graph below shows the

result of this on efficiency of an ideal, and some real propellers.

The most important thing to observe from the graph is that

propeller efficiency is higher as the thrust gets smaller. Because the

thrust load coefficient decreases with both the propeller area and

velocity of the water thrown backward, efficiency also increases with

a larger propeller area and a small water velocity increase. Propeller

efficiency is the ratio between the engines power and the thrust

power. Thrust power is thrust times the velocity of the propeller

through the water.

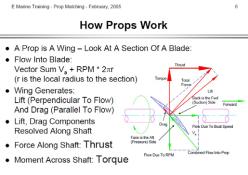

Real propellers are a series of blades that rotate around an axis.

They can be thought of as wings that produce lift and drag, just like

on an airplane. The component along the shaft is thrust and the

component across the shaft is the torque needed to turn the propeller.

The angle of the blade element to the water flow is going to vary

from the hub to the blade tip. This is because the speed of the

rotating blade element increases with the distance from the hub. We

usually want to keep this angle of attack fairly constant. An easier

way to characterize this is called pitch. Propellers were originally

called screw propellers and the pitch was the amount this propeller

would “screw” itself through the water in one revolution. Another

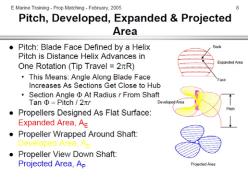

important basic propeller characteristic is the area of the blades. This

can be measured several different ways as the diagram in the next

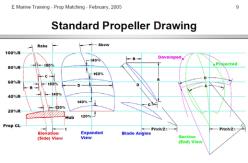

column shows. The standard propeller drawing presents the same

information.