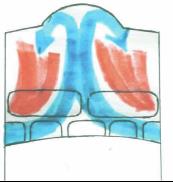

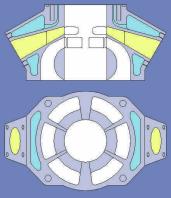

However, the type described as

reverse flow scavenging is being reborn

with modern ideas. The new version is

called the FST or FOS scavenging

system and is being tested in 50 cc

racing motorcycles. The advantage is

that both exhaust and transfer ports can

wrap completely around the cylinder

wall, giving lots of time area. Especially

blow down time area. This better

breathing allows more rpm, therefore

more power. The problem is creating a

good scavenging flow with minimal

mixing and little loss out the exhaust.

The idea is illustrated below.

Notice the transfer and exhaust

passages look very much like those of

the Aprilia 125 except that they go

completely around the cylinder. The

problem is to create a stable column of

air in the center of the cylinder to force

out the residual exhaust. Is it possible

with, around the same scavenging

efficiencies as the loop systems?

PROPWASH

4

April 2013

High Power Two Stroke Design Part 2

(Continued from page 3)

Both the double piston and poppet valve exhaust

engine are in use today, but both have limitations for

high power use. The poppet valve flow is limited both by

restricted area and opening speed, so the maximum rpm

is limited compared to ports. Lots of large two stroke

diesels use this system since high speed isn’t needed. The

double piston engine is mechanically complex, but

otherwise has formed the basis of some very successful

engines. See the Eco Motors engine illustrated in part 1

of the November 2012

Propwash

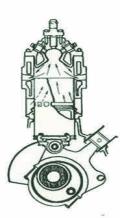

. The sleeve valve is

less complex and doesn’t suffer from immediate rpm

limitations. However, it has never been fully developed.

Because the jet engine was obviously superior for

aircraft, the development before and during World War

II of the only two stroke engine using a sleeve valve, the

Rolls Royce Crecy, was stopped. Single cylinder test

versions of this engine were supercharged to brake mean

effective pressures of over 350 psi (24 bar).

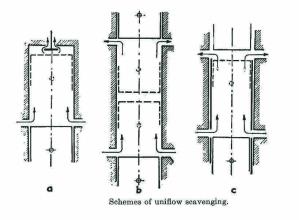

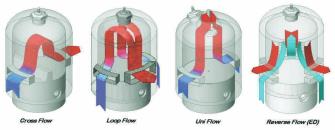

As was also pointed out in part 1, the tuned pipe,

taking advantage of the pulsating nature of the two

stroke engine, revolutionized two stroke thinking. Its performance made up for poorer

scavenging in the simple engine. The picture below shows a comparison of the various

types of scavenging systems used in simple engines. Model engines have used all but

the uniflow type for a long time, but performance seems to be best with loop

scavenged engines so far.

Crecy Sleeve Valve Cylinder