An engine’s power can be increased

by increasing the amount of air flowing

through it and/or the brake mean

effective pressure. The amount of air

flowing through a piston engine is

determined by the size of the cylinder

(displacement), the air density, and the

rpm. The brake mean effective pressure

is determined by many factors including

fuel heating value, air density, and the

efficiency of all the various processes.

These factors were recognized very

early, and most racing classes limit an

engines power by limiting the displace-

ment, air density (amount of super-

charging), and sometimes the fuel. That

leaves increasing rpm as the only way to

move more air through the engine.

Increasing brake mean effective pressure

is a lot harder, especially when fuel type

is limited.

As was mentioned in part one, a two

stroke’s power is limited both by

breathing (the ability to handle more air)

and scavenging (the amount and purity

of the mixture left after the exhaust port

closes). Brake mean effective pressure is

closely related to scavenging efficiency

when everything else is equal. Even with

major improvements over the last 50

years, loop type scavenging systems

can’t compare to a four stroke’s

scavenging efficiency. Our model

engines along with small industrial two

strokes have been stuck at break mean

effective pressures of under 100 psi (7

bar) for a long time. Naturally aspirated

four strokes seldom exceed 150 psi (10

bar). The best racing two strokes can

reach 200 psi (14 bar) but the pipe is

supercharging the cylinder. A top fuel

dragster engine can reach 1500 psi (100

bar) with a combination of high super-

charge and nitro.

Let’s look at some other two stroke

scavenging systems. Uniflow

scavenging, where the incoming air

enters at one end of the cylinder and

pushes the exhaust out the other end, is

the gold standard of two stroke

scavenging systems. In the past, three

methods of uniflow scavenging have

been used. The poppet exhaust valve

engine, the double piston engine, and the

sleeve valve engine. See the pictures on

the following page.

Continued on page 4

PROPWASH

April 2013

3

policy to pay first. Then, once your primary policy has paid what it covers, NAMBA’s

secondary policy goes into effect. This would cover such things as deductibles,

amounts over the policy limits, etc. If you do not have health insurance of any kind,

NAMBA’s policy covers you the same as if it were a primary policy. There are of

course deductibles on both of these coverages. $500 on the liability coverage, and

$100 on the personal accident coverage. However, in the past, NAMBA has been able

to pick up the cost of these deductibles, and we assume we will continue to do so in

the future as long as funds permit.

As you can see, your NAMBA insurance provides you with the best protection

available through any of the model boating organizations. Hopefully, you will never

have to make use of this coverage, but if you do, you can be assured that you are

covered. Continued availability of this exceptional coverage is of course to some

degree up to you. Make sure that you are aware of all of the safety regulations, and use

common sense in your running. Preventative medicine is always better than having to

resort to a cure. By avoiding needless accidents, we can insure that the coverage will

be available when really needed.

High Power Two Stroke Design Part

2

By Lohring Miller

NAMBA Safety Chairman

The following is part two in a series of three articles. Please go to the November 2012

Propwash on the NAMBA web site if you missed out on part one.

Before we continue our look at future directions in two stroke design, we need

some basic definitions and some engine history. I’ll use British engineering units for

these examples. Engines were created to do work. Work is defined as moving a weight

a distance, measured in foot (the distance) pounds (the weight). Power is how fast this

work is done or foot-pounds per second. One horsepower is 550 foot-pounds per

second. Since we’re racing, power is the basic measure of engine merit we want to

look at. The torque in foot pounds or amount of work an engine can do is found at a

particular rpm by dividing the horsepower by that rpm and multiplying the result by

5252. This torque can always be increased with gearing to match your needs, but the

power will not increase. Therefore, the work won’t get done any faster.

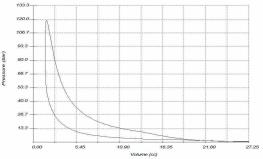

Internal combustion engine power is closely related to the amount of working fluid

(usually air mixed with a little bit of fuel and/or combustion products) passing through

it. In piston engines this is the piston’s displacement times the rpm. The combustion

process in the cylinder increases the pressure of this air and it expands, pressing the

piston down. The result of one revolution is a cylinder that decreases then increases in

volume with a varying internal pressure. That’s shown on the pressure volume

diagram below. The area inside the graph represents the work produced in a single

cycle. The average pressure acting on the piston is called the mean effective pressure.

A more easily calculated figure of merit is the brake mean effective pressure, or the

average pressure acting on the piston needed to produce the power measured on a

dynamometer.