The following is an extract from the

movie as shown by the PhD candidate

VD Jimenez at CMT at the University of

Valencia. It shows how the above pulses

created by a tuned pipe influence the

flows in the engine cylinder.

Notice how the red inflow from the

transfers flows up the back wall of the

cylinder and out the exhaust, pushing out

the blue combustion products. This is

encouraged by the low pressure pulse at

4 in the above picture. The high pressure

pulse at 2 above then pushes the

somewhat pure mixture in the pipe back

into the cylinder. This is about as good

as it gets in a two cycle. There are still

some exhaust products in the cylinder at

exhaust port closing, but the mixture is

significantly supercharged. This engine

develops 54 hp from a 125 cc cylinder.

A 26 cc engine that was this highly

developed would have around 11 hp at

13,000 rpm. Since the smaller engine

could easily turn 18,000 rpm, you could

expect over 15 hp.

Aprillia RSW125 Scavenging

1. CMT own their own RSW125 and

measured it fully to model in 1D and 3D.

2. The rpm value working back from

port duration and time seem to be around

12000.

3. Blue is burnt gas and red is fresh gas.

4. This is a single cycle event as it starts

with uncontaminated charge in the

transfer ports.

5. The interesting thing is how good the

scavenging is; before the plugging pulse

arrives the cylinder is close to a 100%

scavenged. (page 8)

6. The obvious next improvement would

be to increase the delivery ratio to the

point where the exhaust port is also filled

with fresh charge so the plugging pulse

is also fresh charge uncontaminated.

7. Not heating the fresh charge in the

exhaust port duct should show the

improvement as found by Jan Thiel.

8. It seems the shape and down angle of

the Arillia port as developed by Jan

Thiel on his flow bench not only

promotes flow but also the lower

turbulence tends to prevent mixing

between the escaped fresh charge and

the burnt gas.

(Continued on page 8)

PROPWASH

October 2014

7

High Power Two Stroke Design – Postscript

By Lohring Miller

NAMBA Safety Chairman

After reading the previous articles in this series, it’s easy to get lost in all the

details. Below are excerpts from two papers that summarize what we are trying to do

with pipe and port design. The first is by Neels van Niekerk. The second is the only

publically available computational flow dynamics (CFD) analysis I’m aware of for a

high performance, tuned pipe engine.

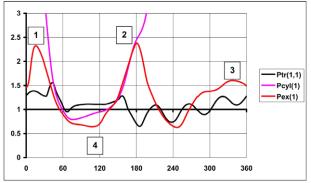

Pipe Pulse Design

I think a successful design of a pipe combines the following:

1. The obvious, that pressure pulse 1 must be reflected to arrive just before Ex-port

closure 2.

2. There must be a suction pulse 4 during the transfer open period.

The tricky bit in order to get really high suction and plugging pulse values, pressure

pulse 2 which is reflected from the ex-port must again be reflected from the reverse

cone to arrive just before Ex-port opening 3. This will then get reflected in back down

the pipe and travel just in front of the new pulse 1, combining with it to increase its

amplitude and thus the amplitude of the suction and plugging pulses.

This last point is only achievable with an Ex-port timing of roughly between 190

and 200 degrees which is why all GP-bikes use this value and use more and wider

exhaust ports to obtain enough blowdown time area. With very small exhaust duration

or very big exhaust duration this recombination is not possible as the timing is all

wrong and only the classical pipe theory can be used.

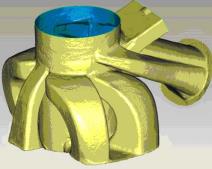

Below is a picture of the Aprilia exhaust and transfer passages as an introduction to

the next section.