PROPWASH

November 2012

15

data. Getting enough blow down area is tough. The blow down period is the time

between exhaust port opening and transfer port opening. This period partially exhausts

the cylinder and, more importantly, creates a powerful exhaust pulse. Since the

maximum width of an exhaust port is around 70% of the cylinder bore, divided and

triple exhaust ports were developed. The remaining wall area is used for the transfer

ports.

The second requirement is good

scavenging of the cylinder. In a four stroke

the piston forces the combustion products

out the exhaust during a full upstroke of the

piston. In a two stroke this process has less

than half the time at the same rpm as a four

stroke and is accomplished by the incoming

air. A two stroke’s power is a sensitive

measure of its scavenging efficiency.

Experimenting with transfer port layouts

and angles has still not completely solved

scavenging issues in the Schnürle style

scavenging system. However, most current

high power engines use four transfer ports with a small single rear boost port. The

transfer passages need to be gently curved for good directional control of the incoming

mixture. The up angles on the transfers are partly determined by the bore/stroke ratio

and piston speed. The goal is to have the flows collide just above the piston to create a

rising column that doesn’t mix with the combustion products. This column needs to

stay along the back side of the cylinder away from the exhaust to avoid too much loss

out the exhaust port. A very interesting series of visualizations of this process in a

piston port non piped engine can be found at: http://aam.mathematik.uni-freiburg.de/

IAM/homepages/trescher/2StrokeEngine/movie/2StrokeEngine_MPEG1.mpg

The third requirement is a tuned exhaust system that creates a low pressure in the

cylinder during the time the transfers are open and a high pressure pulse after they

close. The low pressure pulse helps evacuate the cylinder. It also encourages flow out

of the crankcase through the transfers

and into the crankcase through the

intake. The high pressure pulse

returns fresh mixture that has flowed

out the exhaust port and supercharges

the cylinder. The tuned pipe is

responsible for more of the simple

two stroke’s power than any other

part of the engine. Notice in the graph

below that this supercharge amounts

to 2.4 atmospheres absolute or a boost

pressure of 20 psi above atmospheric

pressure.

Today the Aprilia 125 represents

the peak of modern small two stroke

development. This engine develops

54 horsepower at the transmission output shaft. That’s over 400 horsepower per liter,

twice what Kaden’s engines produced. From the lessons learned in their 125 cc race

engine program, engineer Jan Thiel predicted that a two cylinder 50 cc engine could

develop 39 horsepower at 23,000 rpm. That would be over 19 horsepower from a 25cc

racing engine, about three times the power developed by the industrial type engines

now used in model boat racing.

Is this the best that can be done? What old and new ideas promise to give two

strokes even more power? Part 2 will explore the future.

Bill Wisniewski is generally

attributed with bringing this technology

to model engines. In 1964 he brought

his Theobald-Wisnewski

Association “wart” engine (from the

bump on the casting for the boost port)

to the FAI control line speed

championships and won. In 1966, he

added the tuned pipe, and the Americans

were 1, 2, 3 with this technology. Bill

gave a talk at the event explaining the

details of his engine and pipe. He

published a pipe design article in the

March 1967 issue of Model Airplane

News. Bill’s Pink Ladies dominated

control line speed events for years. He

was responsible for the design of many

of K&B’s high performance engines and

worked there from 1961 almost until his

death in 2007. The Russians petitioned

the FAI to make tuned exhaust systems

illegal, but they, along with Schnürle

porting, are still a design feature of most

high performance model engines.

What distinguishes the modern, high

power small two stroke? The first

requirement of a high rpm engine is

sufficient flow area in the intake,

transfer, and exhaust ports. Empirical

methods have identified the time area

required to generate this flow for a

particular power at a given rpm. Time

area is the “average” open time and area

of a port that determines how much

fluid can flow through it in an engine

cycle. The program I use, Engine

Mod2T, calculates this from the input

Bill Wisniewski in 1966

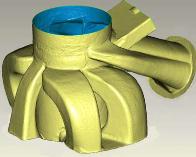

The Aprilia designed ports

The Aprilia transfer passages