PROPWASH

October 2011

7

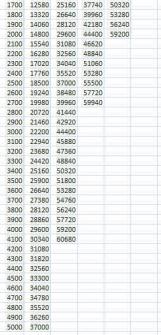

For stable operation a power plant needs to operate in an area where the torque rises

as the rpm drops. That way, when increasing propeller load reduces the rpm, the

motor’s torque increases to continue to rotate the propeller. This means you always run

around or beyond the power peak on an internal combustion engine at full throttle. See

the green area on the graph. If the propeller load increases to pull the rpm into an area

of decreasing torque, the rpm will continue to drop until the engine stalls. That doesn’t

take much change in propeller immersion. The torque rise in an internal combustion

engine is much less than in an electric motor. An electric motor’s torque and power

will always increase rapidly with increasing load until something melts or the

controller’s overcurrent protection kicks in.

That means propping an electric boat is very different. It’s immediately obvious

when an internal combustion engine is over propped. The engine sags or stops. It’s not

immediately obvious that an electric motor is trying to pull too big of a prop. The most

direct way to check is to measure the current draw from the motor. The new Castle ICE

controllers have built in data loggers that do this. The Eagle Tree data logger will also

measure current. Indirect methods involve measuring component temperatures and

measuring the input to the battery from the charger after a run. The rated maximum

continuous current for the motor in our example is 100 amps. Fortunately, the motor

Continued on page 8

Another important relationship is

electrical resistance. The current flow is

the voltage divided by resistance.

Increasing resistance reduces the current

and therefore the power. This wasted

power turns up as heat. In watts it is the

current squared times the resistance.

One watt is 3.4 btu’s per hour. A btu

will raise one pound of water one degree

F. That means our 80% efficient power

plant (444 watts of waste heat) generates

25 btu’s per minute. That would raise

the temperature of a pound of uncooled

copper or iron around 250 degrees in a

minute.

But wait a minute. How can an

electric power plant with only 2.4

horsepower drive an outboard tunnel as

fast as a nitro engine? Even a K&B Pro

has 3.5 advertised horsepower.

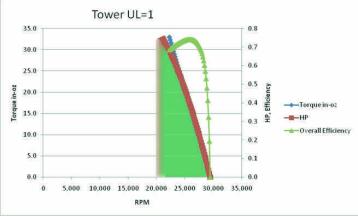

Remember, the power output from an

electric motor is not related to rpm. To

make this happen, the torque increases

very rapidly as the rpm drops. An

internal combustion engine’s torque is

approximately constant. See the two

graphs below. The first is for a typical P

limited power plant and the second is

for a model gasoline engine.